Electric Car Motors Explained

Electric motors use electrical energy from a rechargeable battery pack, converting it into the propulsion that makes your car drive. Just as internal combustion engines have many different designs (see the Wankel rotary engine in Mazda RX-7 as an example) there are different types of electric motors.

Here are the basics on different types of EV motors, EV-motor-related terms, and more.

EV Motor Glossary

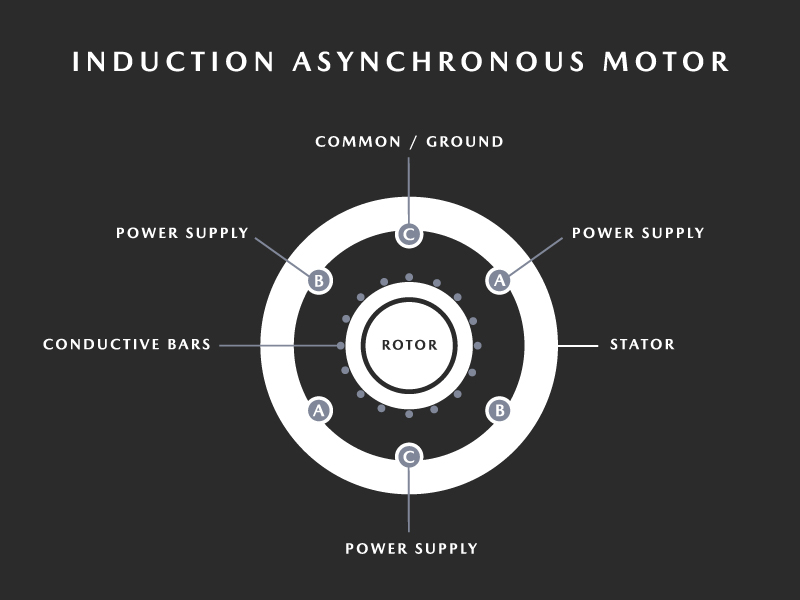

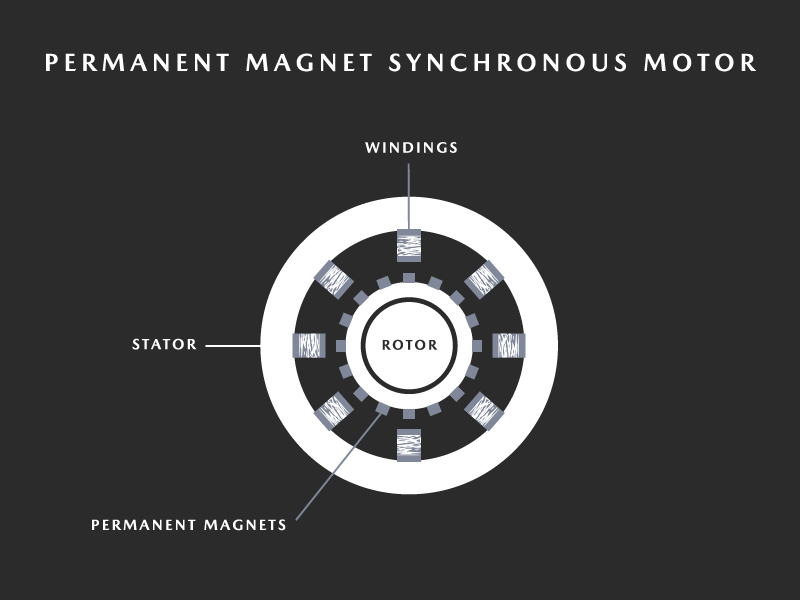

- Stator: The stator is the stationary component of an electric motor. It is composed of an outer frame, core, and windings. Using the energy supplied by the car battery, it creates a rotating magnetic field.

- Rotor: The rotor is the rotating center section of an electric motor. It is attached to a shaft that, when driven by the rotating magnetic field supplied by the stator, produces the electric motor’s output.

- Alternating Current (AC): Alternating current is an electrical current that changes, or alternates, the direction of charge flow many times per second. The frequency of the alternating cycle is measured in hertz. In the power supply for a North American house, for example, the AC current direction typically alternates 60 times per second, hence the “60 Hz” label on most electrical appliances manufactured for US residents.

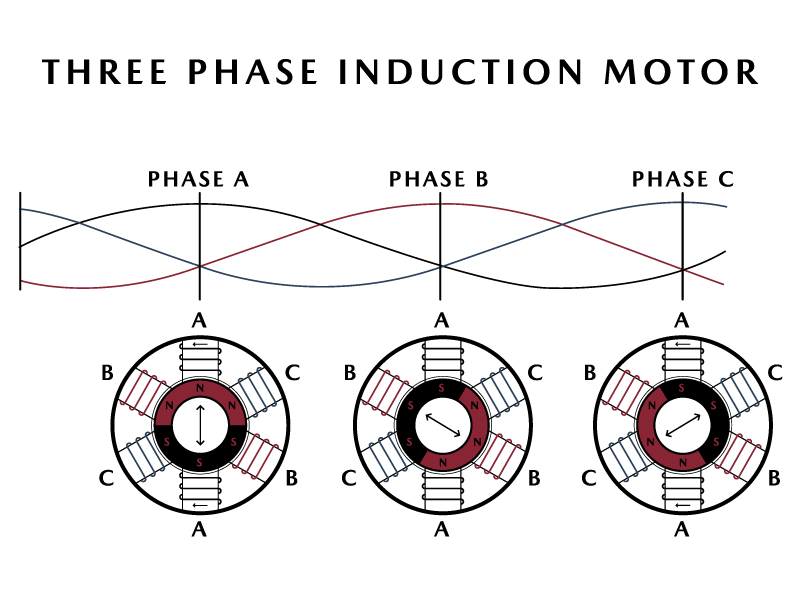

Most automotive electric motors use a three-phase AC system, in which a single 360° rotation is split into three 120° segments, for more efficient power generation and transmission.

- Direct Current (DC): Direct current is electrical current that always flows in the same direction. All batteries, including those in electrified vehicles, currently use DC. The DC current is converted to AC power by an inverter and/or the EV's power control systems.

- Rotating Magnetic Field (RMF): The RMF is the magnetic field that results when the battery applies power to a stator’s coils, thereby inducing rotation of the rotor. Note that the exact process behind RMF generation varies by motor type. Regenerative braking – charging the battery by using the vehicle’s motion – occurs when this process is reversed.

Electric car motor basics: EV motor 101

Typically, all-electric vehicle motors use a stator and rotor, and most use magnets or electromagnets. By constantly alternating current polarity, the motor uses those attracting/repelling magnetic forces to rotate the output shaft via the rotor, turning electrical energy into mechanical energy—specifically torque—to move the vehicle. Electric motors require very little rotation speed to provide abundant torque and have only one moving part—the rotor—which is why the transmissions in EVs are so radically different from those found in Internal Combustion Engines (ICE).

Electric vehicles also typically have advanced control and charging circuitry to manage electrical loads, both AC and DC. The “whine” or “noise” often attributed to electric vehicles comes from these electronics more than from the motor(s).

See our articles on how to charge your EV or PHEV and different EV charging types for more information.

Types of electric car motors

AC induction asynchronous motor

In this motor design, patented by Nikola Tesla in 1888, AC voltage is applied to windings – typically made of copper, aluminum, or alloys – that generates an RMF in the stator, inducing voltage in the rotor. This voltage causes current to flow, which produces an RMF in the rotor. The force between these magnetic fields drives the rotor. Since the rotor RMF “chases” the stator RMF by about five percent, this motor is called asynchronous; in synchronous motors, rotor and stator RMF speed are the same.

AC induction motors generally offer efficiency and excellent reliability. These motors do not have the coasting drag of a Permanent Magnet Synchronous Motor (PMSM) and are usually considered to be good for on-demand applications, as in hybrid drive systems, where the motor is only used when needed, as opposed to continuous use. The components of AC induction motors also do not include rare earth materials.

Induction motors generate a magnetic field within a metal cage on the rotor using electrical current, resembling the function of an electromagnet. This magnetic induction requires a small misalignment between the stator and rotor fields, termed "slip," which is what characterizes the motor as "asynchronous."

Brushed current excited AC synchronous motor

Brushed motors are typically uncommon in EV motors because of concerns about brush wear or failure. For context, the brush is how the electrical current can be connected to a rotating shaft; the brush wears over time but is not technically considered a moving part. This AC synchronous motor works much like a PMSM except, instead of rare earth materials, it feeds DC power to broad copper lobes in the rotor (via brushes) to create the electromagnetic field. It is generally less efficient, particularly at low speeds, but is also currently relatively low-cost to produce.

Brushless DC motor (BLDC)

This type of motor employs permanent magnets on the rotor and electromagnets on the stator and uses an external controller to switch varied windings on and off polarity between positive and negative charges to generate torque. Brushless DC motors are known for their longevity, low maintenance, and efficiency, but are most costly to manufacture.

Permanent Magnet Synchronous Motor (PMSM)

PMSMs look like BLDC motors but have permanent magnets on the rotor, so no power is needed to generate the RMF. These motors have excellent power density and thermal efficiency (92-97%), especially at low speeds, but they’re both heavy and usually more expensive to produce, in part because their manufacture requires the use of rare earth metals. Permanent magnet synchronous motors also suffer from what is called “back electromotive force.” Back electromotive force occurs when drag is added when the motor is not powered at speed, which creates the need for cooling.

The rotor's magnetic field comes from strong permanent magnets, and it spins in harmony with the stator's magnetic field, explaining the "synchronous" aspect of its name.

Switched reluctance motor (SRM)

In the world of electric motors, reluctance is synonymous with magnetic resistance. This motor uses multiple electromagnetic north/south poles on the stator that are switched on and off (as within a BLDC’s windings). These motors offer moderate power density and thermal efficiency and are typically known for their reliability and fault tolerance. However, they do require relatively complex controllers and normally do not offer a smooth driving experience.

Synchronous Reluctance Motor (SynRM)

This is a relatively new design that promises good power density, lower production costs, and less noise. It also doesn’t use rare earth metals.

The SynRM contains a rotor that is carefully shaped to direct magnetic flux. Some feature magnets (often made of simple ferrite) embedded within the rotor to minimize the back electromotive force drawbacks of the PMSM.

Mazda’s CX-90 PHEV: An example of electric motors in action

Spotlight on Mazda SKYACTIV® TECHNOLOGY

While electric motors present exciting opportunities for the future of vehicle power, much work is being done to improve the standard gas-powered Internal Combustion Engines (ICEs) of today. The Mazda Skyactiv® Technology strives to combine the best aspects of gasoline and diesel engines. Exceptional fuel efficiency provided by Mazda vehicles has been recognized multiple times by the U.S. Environmental Protection Agency (EPA). Depending on the model selected, the CX-90 features one of two engines as part of the e-Skyactiv®-G program: a 3.3-liter Inline 6 or a 2.5-liter 4-cylinder engine in the PHEV.

Keep at the forefront of EV Engineering with Mazda

At Mazda, we believe that every drive should inspire, regardless of the vehicle’s power source. Our EV technology is designed to meet your practical driving needs without losing the performance-focused driving experience and unparalleled craftsmanship you know and love.

The electric powertrain in the CX-90 PHEV, and CX-70 PHEV and our e-Skyactiv® Technology are just the beginning, and along with the CX-50 Hybrid, Mazda Motor Corporation aims to achieve carbon neutrality at global factories by 2035, and throughout the entire supply chain and through the entire vehicle life cycle by 2050.

Join us. Explore the Mazda CX-90 PHEV, CX-70 PHEV, and the CX-50 Hybrid performance, design, technology, safety and utility features, shop the Mazda range online, or test-drive one at a Mazda Dealership near you.

This article is intended for general informational purposes only and is based on the latest competitive information available at the time of posting. Information herein is subject to change without notice and without Mazda incurring any obligations. Please review a variety of resources prior to making a purchasing decision. Visit Resource Center for more articles.