What Is Torque Vectoring?

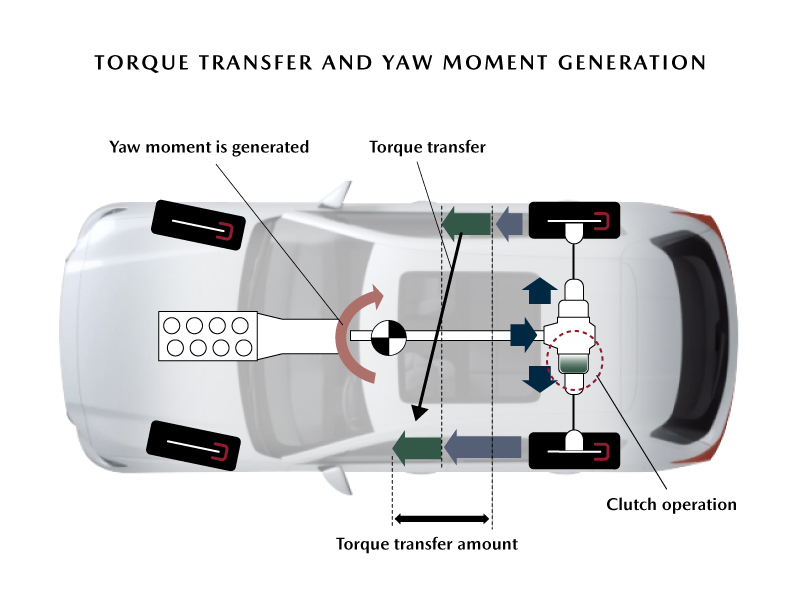

In the simplest terms, torque vectoring allocates torque between a vehicle’s right and left drive wheels, providing added steering response during cornering. It can be applied on front, rear, and all-wheel drive cars.

Torque vectoring terms to know:

● Torque: This is the twisting force that causes an object to rotate around its axis. In cars, torque comes from the combustion engine or electric motor and drives the wheels. Torque is the work an engine can do, while horsepower is the measure of how quickly it can do that work.

● Differential: The differential is the mechanical device that allows a vehicle’s wheels to turn at different speeds. This process is necessary when your vehicle is making a turn; the wheels on the side of the direction you’re turning have to travel less distance than the wheels on the outside of the turn.

● AWD: All-wheel drive is a system that can drive all the vehicle’s wheels simultaneously. Many AWD systems work (automatically) as front or rear-wheel drive until tire-slip is detected and all four wheels require torque.

● Clutch packs: A clutch pack is a coupling device that is activated electrically and connects the driveshaft to the rear differential. The clutches work to maintain synchronization between the tires, transferring more torque to the tire that has the best grip while reducing torque transfer to the tire that has less grip.

How does torque vectoring work?

By delivering torque to left and right wheels independently, torque vectoring can affect how a vehicle turns under power. To understand how this works, think of paddling a canoe. If you paddle more on one side, your canoe will turn toward the side that is paddling less. The same principle can be applied to steering a wheelchair. In both instances, the “driver” is torque vectoring by applying more arm speed or effort on one side in order to change directions.

Torque vectoring in a vehicle is accomplished with specialized differentials, clutch packs, and controlling software that directs more torque to the “outside” (opposite the direction you’re turning) wheel or wheels.

For example, in a car with torque vectoring, the left rear wheel will slightly get more power if you’re making a moderate right bend on an interstate cloverleaf on-ramp. This will push the car slightly to the right. Which ultimately results in less required steering wheel movement and, when applied at maximum effort, higher speed.

Torque vectoring vs. AWD

Torque vectoring is a directional aid, improving steering response and handling as the tires approach their maximum grip level and stability. It can be applied to any driven axle, whether the car has one or two.

All-wheel drive is a drive system’s capability of driving both front and rear axles, with a commensurate increase in acceleration traction. All-wheel drive and torque vectoring are not mutually exclusive; some all-wheel drive vehicles offer or come standard with torque vectoring.

Differential-based torque vectoring

Differential-based torque vectoring is technically the most “accurate” type of torque vectoring (considering the above definition) because it entails varied left/right torque provided by the engine or electric motors.

Differential-based torque vectoring can be designed in many ways but generally speaking, it takes a sophisticated differential to provide a tire or tires on one side of your vehicle with more torque or speed than those on the other.

In many cases, clutch packs determine how much torque gets sent to either side. While most drivers won’t feel any of the clutch pack or differential action, many people will feel the effect it has.

On some more “sporting” vehicles, you can adjust how aggressive you want the torque vectoring to be, while on others you can “lock” that axle at lower speeds (for more severe off-highway travel) using a driver-selectable switch or menu setting.

Brake-based torque vectoring

A bit of a misnomer, brake-based torque vectoring uses the brakes to limit torque being applied to a wheel rather than apportioning more torque to the other wheels. By limiting the torque applied to one wheel, the wheel on the other side of that axle technically “applies” more torque, and the vehicle will turn towards the side of the vehicle on which a wheel is being braked.

The same hardware that provides “brake torque vectoring” provides stability control in much the same way. For example, if you enter a right-hand turn too fast and with too much steering wheel angle for the tires’ adhesion limits, the stability control will likely apply the right rear brake (and probably cut the engine throttle) to help pull the car to the right. A good analogy is the mechanics of driving a bulldozer or tank — stop the tracks on just the left side and the bulldozer will go to the left.

“Brake torque vectoring” is commonly used for vehicle stability and not as a performance aid — as you can imagine, most vehicles go faster without applying brakes.

Electronic torque vectoring

Electric and hybrid vehicles — particularly performance hybrid vehicles— often deliver torque vectoring by using two electric motors, run independently, on the same axle. This is a relatively simple arrangement; the motors are already there, so the only thing needed to apply torque vectoring is programming that drives one motor with more energy than the other side at the appropriate times.

Torque vectoring advantages and disadvantages

Torque vectoring pros

● Cornering stability is improved and closer to what the driver “asks for” as determined by onboard sensors.

● Improved lap times on a track and handling limits under acceleration.

● The traction aid of locking differentials, but with automatic application available in all speed ranges.

Torque vectoring cons

● It adds complexity and a higher price.

● If you use your vehicle merely as a transport appliance and are not an enthusiast, you may never fully enjoy the benefits.

More considerations for buying a vehicle with torque vectoring

If you’re interested in a vehicle that has or offers torque vectoring, be sure to test drive the vehicle on a route with plenty of corners, and then do the same in the closest-match vehicle that does not have it.

If you don’t notice a difference — or won’t normally drive that way — you may not need it. Honestly assess if you want it for performance, stability, or just keeping up with the Joneses.

See our resources on Safety Features, What to Consider for Buying a Used Vehicle, and Buying an EV for more guides.

What is the Mazda G-Vectoring Plus and how does it differ from torque vectoring?

The Mazda G-Vectoring Control Plus system is the latest iteration of G-Vectoring Control introduced in 2016. G-Vectoring Control Plus is not a torque vectoring system but rather a system that employs very subtle and simple programming to smooth vehicle response to driver inputs and improve cornering feel and stability. It achieves for you automatically what a professional driver typically does manually on the track. There is no artificial feeling that some torque-vectoring systems have, no additional hardware, and it’s standard on all Mazda vehicles except the Miata MX-5.

G-Vectoring Control Plus adjusts engine output and applies braking during cornering for improved balance and smoothness. Using steering wheel sensors and other inputs, the car determines whether the driver is turning into a corner and the system responds by ever-so-slightly reducing engine torque, very slightly shifting the weight of the car to the front wheels. This in turn loads the suspension components and delivers a slightly quicker response to your steering wheel movement.

As your car turns the corner, the system will feed more power back in to maximize steering consistency and balance, and as you exit the corner the car will — unless you’re a really smooth driver — subtly and momentarily apply the front brake opposite the direction of the corner to smooth the weight transfer to the rear wheels as you apply more throttle.

Although the changes the car makes are extremely subtle, you may well notice how the car feels a little more stable in cornering and doesn’t require as much steering movement, which can reduce driver fatigue, particularly on long trips.

Experience the joy of driving with Mazda

Every Mazda aims to elevate the joy of driving through their long-standing philosophy of Jinba Ittai — being at one with your car. Whether it’s the fun-built-in MX-5 Miata or any of our award-winning CUVs, the car and the driver are partners to make both better.

Want to speak with someone about your options? Connect with an experienced representative at your local Mazda Dealer to receive personalized guidance, explore available models firsthand, go on a test drive, and turn your Mazda dream car into a reality.

This article is intended for general informational purposes only and is based on the latest competitive information available at the time of posting. Information herein is subject to change without notice and without Mazda incurring any obligations. Please review a variety of resources prior to making a purchasing decision. Visit Resource Center for more articles.